Are commonly known as hard alloyed balls, which refer to balls and rolling balls made of hard alloy materials. Hard alloy balls have advantages of high hardness, good abrasion resistance, anti-corrosion, anti-bending and adaptable to tough working environment, and can replace all steel ball products. Type of tungsten carbide ball: tungsten carbide ball is a kind of powder metallurgy product sintered in a Vacuum furnace or hydrogen reduction furnace, mainly composed of micron sized carbide (WC, TiC) powders of high hardness refractory metals, with cobalt (Co) or nickel (Ni), molybdenum (Mo) as binder. Hard alloy ball hardness ≥ 90.5, density=14.9g/cm3.

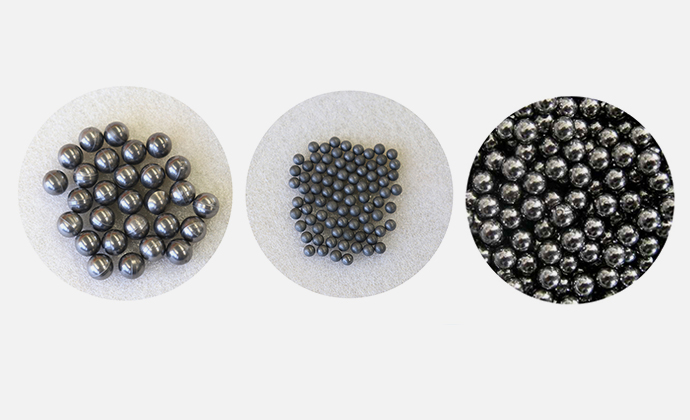

There are three types of tungsten carbide mill balls: tungsten carbide balls with waist band, tungsten carbide precision mill balls.

|

Parameters of Tungsten Carbide Balls |

|||||

| Model No. | Yg6 | Yg6X | Yg8 | Yg10 | Yg15 |

| WC % | 94 | 94 | 92 | 90 | 85 |

| CO % | 6 | 6 | 8 | 10 | 15 |

| Density(g/cm3) | 14.5-14.9 | 14.6-15 | 14.5-14.9 | 14.3-14.7 | 13.9-14.2 |

| Hardness HRA | 89.5 | 91 | 89.5 | 89.5 | 87 |

| Abrasion resistance Hardness N/cm3 | 1380 | 1500 | 1600 | 2200 | |

1) Main ingredient of tungsten carbide ball is WC-CO, which owns high hardness and good abrasion resistance. Its toughness is better than YG6 alloy ball. There also are other good anti-impact and anti-vibration components.

2) High density: Its hardness reaches 15.1g/cm3, little porosity, extra abrasion resistance and anti-corrosion, ten times of life cycle than common tungsten steel ball.

3) High precision: less than 0.001mm tolerance. Smooth and shining surface without pocking mark, because it has been processed by strengthening treatment which is Tencan’s unique manufacturing technology.

4) Small lot production is acceptable.