Stirred ball mill mainly consists of jar with inner grinding media, stirring device and other auxiliary devices such as recycling device, cooling device, timing device, speed adjusting controller, and etc. Its advantages of high efficiency and fine granularity meet technological requirements of various processes. Stirred ball mill is a kind of ideal equipment that are used to crush new materials and research painting for universities, research centers and enterprises because of its features of small batch, low power and low price.

| Main Parameters of Stirred Ball Mill | |||||||||

|

Model NO. |

Rotate

Speed (rpm) |

Volume (L) |

Load

Capacity (L) |

Power Supply (KW/V) |

Available Jars |

Feed Size

(mm) |

Output

Granularity (μm) |

Speed Control Mode |

Catagory |

| JM-1L | 50-1400 | 1 | 0.35 | 0.37KW/220V | Stainless Steel

Nylon Alumina Ceramic PU Zirconia Agate PTFE |

≤5 | ≤1μm | Frequency

speed adjuster |

Laboratory scale |

| JM-2L | 50-1400 | 2 | 0.7 | 0.37KW/220V | ≤5 | ≤1μm | |||

| JM-3L | 50-1400 | 3 | 1.05 | 0.37KW/220V | ≤5 | ≤1μm | |||

| JM-5L | 60-600 | 5 | 1.75 | 0.75KW/220V | ≤5 | ≤1μm | Frequency

speed adjuster or Fixed speed setting For buyer’s option |

Small Type |

|

| JM-10L | 60-560 | 10 | 3.5 | 1.5KW/220V | ≤10 | ≤1μm | |||

| JM-15L | 60-380 | 15 | 5.25 | 2.2KW/380V | ≤10 | ≤1μm | |||

| JM-20L | 60-380 | 20 | 7 | 2.2KW/380V | ≤10 | ≤1μm |

Light Type |

||

| JM-30L | 60-310 | 30 | 10.5 | 3KW/380V | Carbon Steel

Stainless Steel Nylon liner PU liner Alumina Ceramic Liner PTFE liner |

≤10 | ≤1μm | ||

| JM-50L | 60-140 | 50 | 17.5 | 4KW/380V | ≤10 | ≤1μm | |||

| JM-100L | 60-140 | 100 | 35 | 7.5KW/380V | ≤20 | ≤1μm |

Industrial Type |

||

| JM-200L | 60-140 | 200 | 70 | 11KW/380V | ≤20 | ≤1μm | |||

| JM-300L | 60-110 | 300 | 100 | 15KW/380V | ≤20 | ≤1μm | |||

| JM-500L | 60-90 | 500 | 170 | 18.5KW/380V | ≤20 | ≤1μm | |||

| JM-600L | 60-90 | 600 | 210 | 22KW/380V | ≤20 | ≤1μm | |||

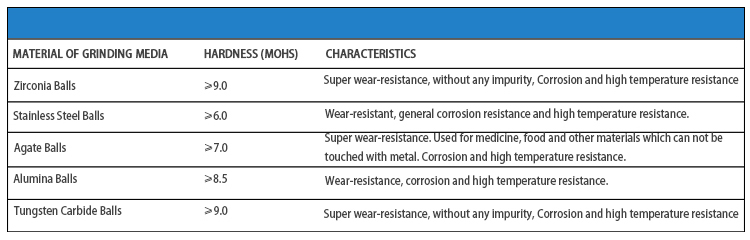

When machine rotates with high speed under driving of main axis and grind media move irregularly at the same time, the grind material can be crushed, ground and sheared into fine granularity powder. The size, shape and matching ratio of the grind media can affect the grinding result. Generally speaking, the bigger the mill media is, the finer the grinding powder is. A proper match ratio of grind medias and proper adjustment of rotation speed can get better grinding effect.

1)High utilization rate of energy, saving energy

2)Granularity is adjustable by adjusting grinding time

3)Less vibration, low noise

4)Simple structure, easy operation

5)Meet requirements of various processes, realize continuous or intermittent production

6)Jar with jacket, easy to control the grinding temperature

7)Customized service is available. Special functions such as timing, speed adjusting, recycling, temperature controlling can be selected and ordered.

8)A variety of grinding jars in different materials is available for customer’s option such as stainless steel, corundum ceramic, polyurethane, zirconia and so on.

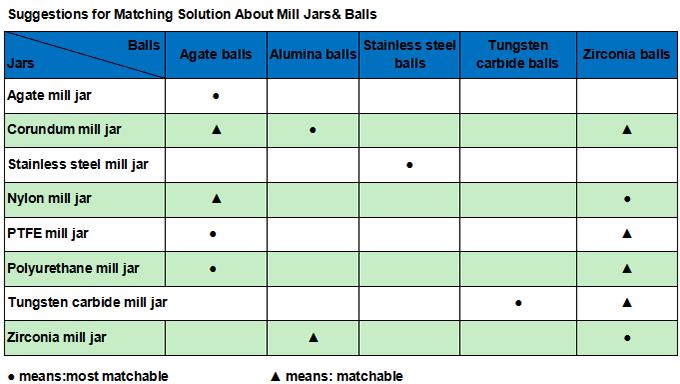

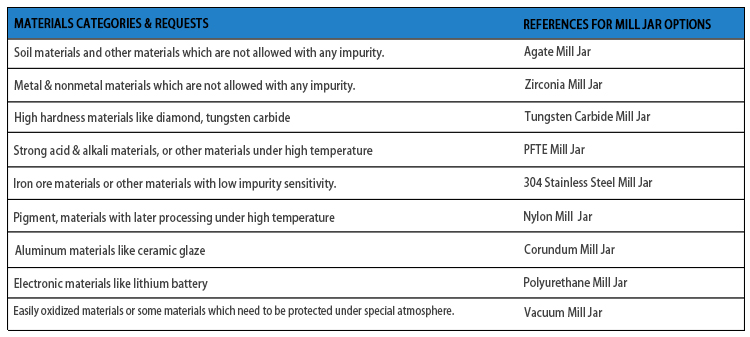

Matchable Accessories of Stirred Ball Mill

Besides the stirred ball mill machines, we have all kinds of mill drums for customer’s option, like stainless steel mill drum, zirconia mill drum, corundum mill drum, nylon mill drum, PU mill drum, and etc. We further produce all kinds of stainless steel or carbon steel mill drums with corundum liner, zirconia liner, polyurethane liner, PTFE liner and nylon liner in different sizes from 30L to 2000L.

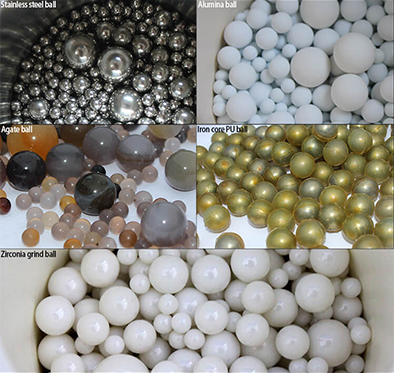

Additionally, we also provide stainless steel mill balls, zirconia mill balls, alumina mill balls, PU mill balls, carbon steel mill balls,tungsten carbide mill balls, etc.

Suggestions for Matching Solution About Mill Jars & Materials

We can also provide all kinds of mill balls like stainless steel balls, zirconia balls, alumina balls, PU balls, steel carbon balls, tungsten balls, agate balls, hard metal balls, silicon nitride balls, high wear resistant steel ball, manganese steel balls, nylon balls, cemented carbide, crystal glass and other special metal materials.

Suggestions for Matching Solution About Grinding Medium & Materials