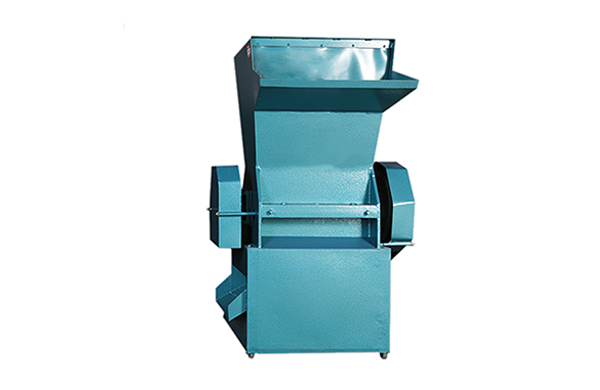

Is divided into claw knife type crusher and flat knife type crusher. Claw knife type crusher is mainly suitable for crushing thick materials, hard material blocks and heads or hard and easily rolling plastics, such as bottles, rubber heads, PVC pipes, wires, bottles, rubber, silica gel or materials with arc; The flat knife crusher is applicable for crushing plastics such as boxes, thin pipe fittings, blow molded parts, bottles, shells, bottle embryos, PE thin plastic products such as PC films, PET bottles, plates, etc.

| Specifications & Parameters of Plastics Crusher (Claw Knife Type) | ||||||

| Model | CK-180 | CK-250 | CK-300 | CK-400 | CK-500 | CK-600 |

| Capacity

(kgs/h) |

50-100 | 150-200 | 200-300 | 250-450 | 400-700 | 450-800 |

| Voltage | 380V-50Hz 3 Phase | |||||

| Power

(KW) |

1.5/2.2 | 4 | 5.5 | 7.5 | 11 | 15 |

| Knife

(pcs) |

9+2 | 6+2 | 9+2 | 12+2 | 15+2 | 18+4 |

| Rotate Dia (mm) | 148 | 225 | 240 | 270 | 280 | 350 |

| Screen hole Dia (mm) | 6 | 8 | 8 | 10 | 10 | 10 |

| Inlet Size

(mm) |

110*180 | 250*160 | 320*200 | 420*220 | 520*260 | 600*240 |

| Weight

(kgs) |

120 | 230 | 330 | 430 | 550 | 780 |

| Dimensions

(mm) |

630*520*950 | 900*700*1050 | 1000*750*1180 | 1060*880*1320 | 1150*1000*1450 | 1200*1060*1650 |

|

Specifications & Parameters of Plastics Crusher (Flat Knife Type) |

||||

| Model | FK-300 | FK-400 | FK-500 | FK-600 |

| Dia of Rotary knife (mm) | 300 | 300 | 300 | 350 |

| Rotary Knife

(pcs) |

3 | 3 | 3 | 9 |

| Length of rotary knife (mm) | 300 | 400 | 500 | 600 |

| Fixed knife

(pcs) |

2 | 2 | 2 | 4 |

| Length of rotary knife (mm) | 300 | 400 | 500 | 600 |

| Capacity (kgs/h) | 180-250 | 250-350 | 300-450 | 350-400 |

| Screen hole Dia (mm) | 8-12 | 8-12 | 8-12 | 10 |

| Power Supply

(V) |

380V-50Hz 3 phase | |||

| Power | 4 | 5.5 | 7.5 | 15 |

| Inlet size

(mm) |

380*200 | 480*250 | 600*250 | 600*300 |

| Weight (kgs) | 240 | 380 | 440 | 850 |

| Dimensions (mm) | 1000*750*1250 | 1200*850* 1400 | 1300*950*1500 | 1050*1100*1600 |

1)Sealed bearing is adopted to keep the bearing rotating well for a long time.

2)Design of the knife is reasonable, it is adopted with alloy steel blade, the output products are evenly granulated, the cutter seat is treated by heat shrinking and tested by strict balance. beautiful and generous of out-looking design.