PE and PEX series of jaw crushers produced by our company, of which PE series are used for coarse crushing of various ores and rocks, and PEX series are often used for medium crushing and fine crushing. PE series have 12 models and PEX series have 6 models.

| Capacity: | 3-500M3/hour |

| Specifications & Models: | PE-150*250 – PE-1200*1500,PEX-150*500 – PEX-300*1300 |

| Scope of Application: | various rocks, ores, limestone, etc |

| Application Fields: | Application Fields: crushing operations of sharp, hot, massive and corrosive materials in mining, building materials, metallurgy, coal, chemical and other industries. |

Specifications & Parameters of PE And PEX Series of Jaw Crusher

| Model No. |

Capacity (m3/h) |

Power (kw) |

Weight (t) |

Maximum feeding

particle size (mm) |

Max Feed Size (mm) |

Adjustment range

of discharge port (mm) |

| PE-150*250 | 1~3 | 7.5 | 1.3 | 125 | 150*250 | 10~40 |

| PE-250*400 | 3~13 | 15 | 2.8 | 210 | 250*400 | 20~60 |

| PE-400*600 | 10~35 | 30 | 6.5 | 340 | 400*600 | 40~100 |

| PE-500*750 | 25~60 | 55 | 10.6 | 425 | 500*750 | 50~100 |

| PE-600*900 | 30~85 | 55~75 | 15.5 | 500 | 600*900 | 65~180 |

| PE-750*1060 | 72-150 | 90~110 | 28 | 630 | 750*1060 | 80~180 |

| PE-800*1060 | 85-143 | 90~110 | 30 | 680 | 800*1060 | 100~200 |

| PE-870*1060 | 145-235 | 90~110 | 30.5 | 750 | 870*1060 | 170~270 |

| PE-900*1060 | 170-250 | 90~110 | 31 | 780 | 900*1060 | 200~290 |

| PE 900*1200 | 100-240 | 110~132 | 49 | 780 | 900*1200 | 95~255 |

| PE-1000*1200 | 190-275 | 110-132 | 51 | 850 | 1000*1200 | 195-280 |

| PE-1200*1500 | 250-500 | 160 | 100.9 | 1020 | 1200*1500 | 150 ~300 |

| PEX -150*500 | 3-15 | 11 | 2.5 | 120 | 150*500 | 10 ~40 |

| PEX -150*750 | 5-16 | 18.5 | 3.5 | 120 | 150*750 | 10~40 |

| PEX -250*750 | 8~35 | 30 | 5.8 | 210 | 250*750 | 15~50 |

| PEX-250*1000 | 13-45 | 37 | 6.4 | 210 | 250*1000 | 15-50 |

| PEX-250*12O0 | 13~50 | 37 | 7.7 | 210 | 250*1200 | 15~50 |

| PEX 300*1300 | 20~60 | 75 | 11 | 250 | 300*1300 | 15-50 |

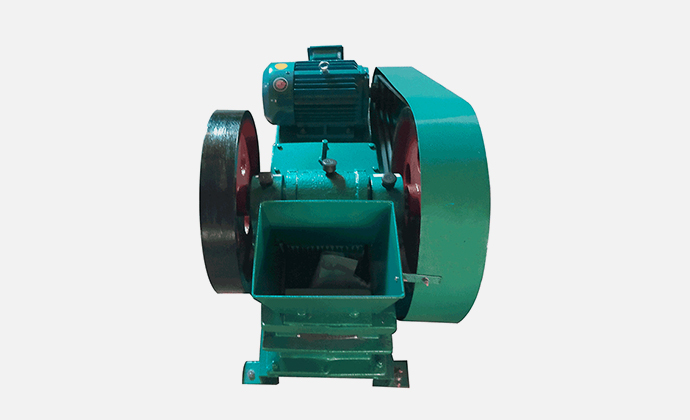

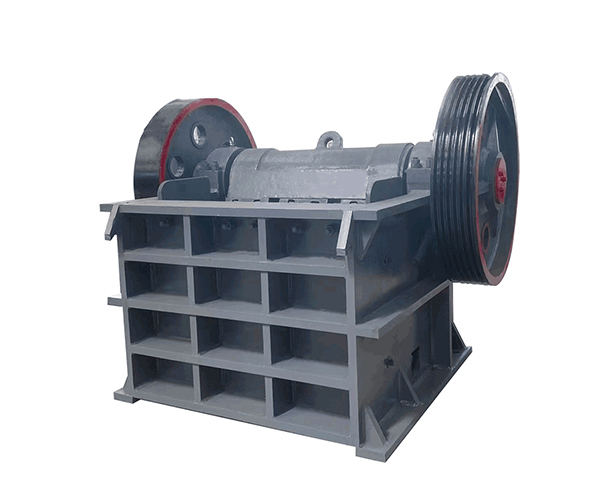

The main structure of lab jaw crusher: frame, eccentric shaft, big pulley, flywheel, side guard ,elbow board, elbow board seat, adjusting screw rod, the return spring, fixed board and adjusted jaw board, and the elbow board can play a role as Protector. The broke drive model of this series jaw crusher is curved extrusion. Motor-driven belt and pulley, through the eccentric shaft to let the jaw up and down, when the movable jaw rises bracket, and the angle Motor-driven belt and pulley, through the eccentric shaft to move jaw up and down movement, when the movable jaw rises, the angle between elbow board and movable jaw plate becomes larger, thus promoting the movable jaw plate close to the fixed jaw plate, while the material can be crushed by squeezed, rubbing, grinding. When the movable jaw fall down, the angle between elbow board and movable jaw becomes smaller, the movable board will leave the fixed jaw board by the action of rod and spring, at the same time crushed material is discharged through crushing chamber.

1.Jaw crusher is adopted with non-friction crushing mechanism. In process of material crushing,

action of the jaw plate onto materials is pure extrusion pressure without relative sliding, hence,

the service life of the jaw plate is long.

2.Simple structure, easy operation and convenient maintenance, stable performance, low operation cost,

Large crushing ratio.

3.The crushing chamber is deep and has no dead angle, which improves the feeding and output capacity.

4.The discharging particle size is uniform with low consumption of energy.

5.Gasket-type discharge port adjustment device is reliable and convenient, with large adjustment range, which increases flexibility of the equipment.

6.The jaw plate is made of high-strength manganese steel and cast in one time, which is characterized by

wear resistance, compression resistance and long service life.

7.The lubrication system is safe and reliable, the parts are easy to replace with small workload of maintenance.

8.Low noise and less dust

Jaw crusher mainly consists of machine frame, eccentric shaft, large pulley, flywheel, movable jaw, side guard plate, the bracket plate, the back seat of the bracket plate, the clearance adjusting screw, the return spring, the fixed jaw plate and the movable jaw plate, among which the bracket plate also plays a safety role.