Micro-computer touch screen planetary ball mill composes of a normal planetary ball mill and the touch operation control system, which improves the equipment’s operating performance. This machine mainly satisfies the customers with the better quality and operation performance. It is widely used in geology, mining, metallurgy, electronics, building materials, ceramics, chemicals, light industry, medicine, environmental protection and other departments.

|

Technical Features of Micron-computerized Planetary Ball Mill |

|

| Drive Mode | Gear drive and belt drive |

| Operation Mode | Two or four grinding jars working together |

| Maximum Capacity | 1/3 of the total volume of mill jars |

| Feeding Size | Soil material≤10mm, other materials≤3mm |

| Output Granularity | Smallest granule reaches to 0.1 μm |

| Rotational Speed Ratio | 1/2 |

| Max. Continuous Operating Time | 72hours |

| Optional Modes of Speed Control | Frequency converter and automatic timing control |

| Materials of Jar | Stainless steel, tungsten carbide,agate, nylon, corundum, zirconia, etc. |

|

Main Parameters of Computerized Planetary Ball Mill |

|||||||

| Model No. | Power (kw) |

Voltage | Dimension (mm) |

Revolution Speed (rpm) |

Rotation Speed (rpm) |

Total Timing (min) |

Alternating Run Time of Forward & Reversal Rotation (min) |

| XQM-2(T) | 0.75 | 220V-50Hz | 750*470*564 | 35-335 | 70-670 | 1-9999 | 1-999 |

| XQM-4(T) | 0.75 | 220V-50Hz | 750*470*564 | 35-335 | 70-670 | 1-9999 | 1-999 |

| XQM-6(T) | 0.75 | 220V-50Hz | 750*470*564 | 35-335 | 70-670 | 1-9999 | 1-999 |

| XQM-8(T) | 1.5 | 220V-50Hz | 900*600*640 | 35-290 | 70-580 | 1-9999 | 1-999 |

| XQM-10(T) | 1.5 | 220V-50Hz | 900*600*640 | 35-290 | 70-580 | 1-9999 | 1-999 |

| XQM-12(T) | 1.5 | 220V-50Hz | 900*600*640 | 35-290 | 70-580 | 1-9999 | 1-999 |

| XQM-20(T) | 4 | 380V-50Hz | 1200*750*920 | 25-215 | 50-430 | 1-9999 | 1-999 |

| XQM-40(T) | 5.5 | 380V-51Hz | 1400*850*1160 | 20-195 | 40-390 | 1-9999 | 1-999 |

| XQM-60(T) | 7.5 | 380V-52Hz | 1600*990*1250 | 27-174 | 40-260 | 1-9999 | 1-999 |

| XQM-100(T) | 11 | 380V-53Hz | 1750*1140*1330 | 27-160 | 40-240 | 1-9999 | 1-999 |

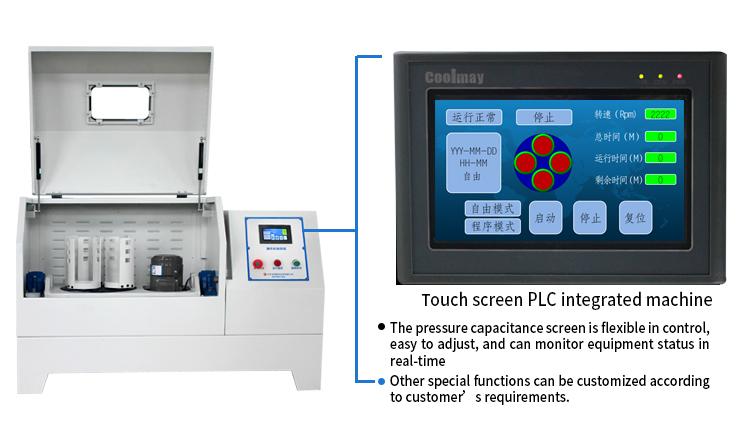

The hardware of the control system adopts well-known brand products, and the control system has powerful functions, including password setting, free programming, multi group program storage and call, process monitoring, and fault alarm. Operation of touch screen is intuitive, simple, and user-friendly, achieving a friendly human-machine interface.

Touch control screen: Easy to operate, simple and intuitive interface, capable of alternating forward and reverse control, with timing and power-off memory functions.

Touch screen PLC integrated machine: The pressure capacitance screen is flexible in control, easy to adjust, and can monitor equipment status in real-time. Other special functions can be customized according to customer requirements.

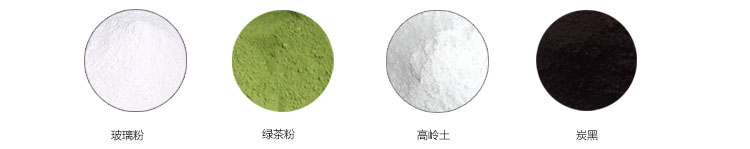

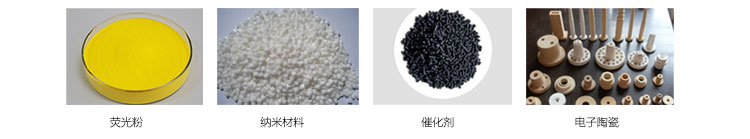

Application of Microcomputer Planetary Ball Mill

Microcomputer planetary ball mill is widely used in geology, mineral, metallurgy, electronics, building materials, ceramics, chemical industry, light industry, medicine, environmental protection and other departments, and is suitable for electronic ceramics, structural ceramics, magnetic materials, lithium cobalate, lithium manganate, catalysts, phosphors, long afterglow phosphors, rare earth polishing powder, electronic glass powder, fuel cells, zinc oxide varistor, piezoelectric ceramics, nanomaterials, wafer ceramic capacitors, MLCC Production fields of thermistors (PTC, NTC), ZnO varistor, dielectric ceramics, alumina ceramics, zirconia ceramics, fluorescent powder, zinc oxide powder, cobalt oxide powder, Ni Zn ferrite, Mn Zn ferrite and other products.

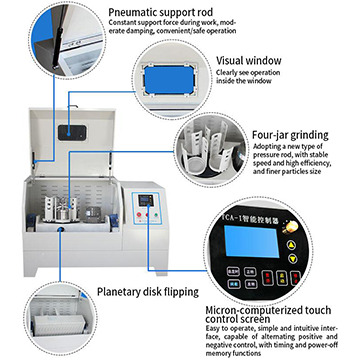

Details of Tencan Micron-computerized Planetary Ball Mill

Adopting a new type of pressure rod, with stable speed and high efficiency, and finer particles size

Accessories

We provide all kinds of mill pots in any matched size, which are made from following materials of agate, Alumina corundum ceramics, zirconia ceramics, silicon nitride ceramics, carborundum ceramics, stainless steel, high wear resistant steel, manganese steel, nylon, PU, cemented carbide, crystal glass, and etc.

We can also provide all kinds of mill balls like stainless steel balls, zirconia balls, alumina balls, PU balls, steel carbon balls, tungsten balls, agate balls, hard metal balls, silicon nitride balls, high wear resistant steel ball, manganese steel balls, nylon balls, cemented carbide, crystal glass and other special metal materials.

|

Recommendation For Matching Solutions About Mill Jars & Materials |

|

| Categories of Materials | Recommended Mill Jars |

| Soil and other Materials which are not allowed with any impurity | Agate mill jar |

| Metal & nonmetal materials which are not allowed with any impurity | Zirconia mill jar |

| High hardness materials like diamond, tungsten carbide | Tungsten carbide mill jar |

| Strong add & alkali materials or other materials at high temperature | PTFE mill jar |

| Iron ore materials with lower impurity sensitivity | 304 Stainless steel mill jar |

| Pigment or other materials with later process under high temperature | Nylon mill jar |

| Aluminum materials like ceramic glaze | Corundum mill jar |

| Electronic materials like lithium battery | Polyurethane mill jar |

| Easily oxidized materials or some special materials which need to be protected under special atmosphere. |

Vacuum mill jar |

|

References About Grinding Medias & Materials |

||

| Materials of Grinding Media |

Hardness (Mohs) |

Features |

| Zirconia Balls | ≥9.0 | Super wear-resistance, without any impurity, corrosion & high temperature resistance. |

| Stainless Steel Balls | ≥6.0 | Wear-resistant, general corrsion resistance, high temperature resistance. |

| Agate Balls | ≥7.0 | Super wear-resistance, used for medicine,food and other materials which can not be contaminated with metal, corrosion, and high temperature resistance. |

| Alumina Balls | ≥8.5 | Wear-resistant, corrsion resistance and high temperature resistance. |

| Tungsten Carbide Balls | ≥9.0 | Super wear-resistance, without any impurity, corrosion & high temperature resistance. |

|

Matching Solutions for Mill Jars & Balls |

|||||

| Items | Agate Balls | Alumina Balls | Stainless Steel Balls | Zirconia Balls | Tungsten Carbide

Balls |

| Agate Mill jar | √ | ||||

| Corundum Mill Jar | ▲ | √ | ▲ | ||

| Stainless Steel Mill Jar | √ | ||||

| Zirconia Mill Jar | ▲ | √ | |||

| Nylon Mill Jar | ▲ | √ | |||

| PTFE Mill Jar | √ | ▲ | |||

| Polyurethane Mill Jar | √ | ▲ | |||

| Tungsten Carbide Mill Jar | ▲ | √ | |||

| √ means: most suitable ▲ means: suitable | |||||