Lab vibration ball mill, also called vibrating ball mill, is a new type of high-efficient milling equipment, there are three models in structures: single-cylinder, double-cylinder and three-cylinder type.

The laboratory vibration ball mill is simple and convenient to operate, reliable in working, easy to clean, and it has strong adaptability under different working conditions, and it can be used for dry and wet grinding.

Lab vibration ball mill is widely used in the fields of electronics, ceramics, chemicals, powdered metals, tungsten, calcium carbide, rubber compounds, magnetic materials, high-frequency ceramic materials in the radio industry, and pharmaceuticals industries.

There are many options of grinding cylinder for user’s requirements such as stainless steel, corundum, zirconia, ceramic tiles, nylon, PTFE, food grade rubber or polyurethane liners, which can be selected at buyer’s option.

|

Parameters of Lab Vibration Ball Mill |

|||||||||||

| Model | Type | Amplitude

(mm) |

Vibration frequency

(rpm) |

Material Load Rate

(%) |

Balls Load Rate

(%) |

Feed size

(mm) |

Output

Size (meshes) |

Motor power

(KW) |

Net weight

(KGS) |

Size of mil jar

(mm) |

|

| ZM-1L | Normal | 5-8 | 1440 | 25% | 60% | <5 | 200-2000 | 1.1-4.0 | 110 | Normal roll jar | |

| ZM-2L | Normal | 5-8 | 1440 | 25% | 60% | <5 | 200-2000 | 1.1-4.0 | 110 | Normal roll jar | |

| ZM-3L | Normal | 5-8 | 1440 | 25% | 60% | <5 | 200-2000 | 1.1-4.0 | 110 | Normal roll jar | |

| ZM-5L | Normal | 5-8 | 1440 | 25% | 60% | <5 | 200-2000 | 1.1-4.0 | 130 | Normal roll jar | |

| ZM-8L | Normal | 5-8 | 1440 | 25% | 60% | <5 | 200-2000 | 1.1-4.0 | 150 | Normal roll jar | |

| ZM-10L | Normal | 5-8 | 1440 | 25% | 60% | <5 | 200-2000 | 1.1-4.0 | 200 | SS. jar | Ø218*313 |

| ZM-10L | Normal | 5-8 | 1440 | 25% | 60% | <5 | 200-2000 | 1.1-4.0 | 200 | PU/Nylon | Ø218*370 |

| ZM-10L | Normal | 5-8 | 1440 | 25% | 60% | <5 | 200-2000 | 1.1-4.0 | 200 | Corundum/zirconia jar | Ø218*395 |

| ZM-20L | Normal | 5-8 | 1440 | 25% | 60% | <5 | 200-2000 | 1.1-4.0 | 200 | SS. jar | Ø245*620 |

| ZM-20L | Normal | 5-8 | 1440 | 25% | 60% | <5 | 200-2000 | 1.1-4.0 | 240 | PU/Nylon | Depends |

| ZM-20L | Normal | 5-8 | 1440 | 25% | 60% | <5 | 200-2000 | 1.1-4.0 | 240 | Corundum/zirconia jar | Depends |

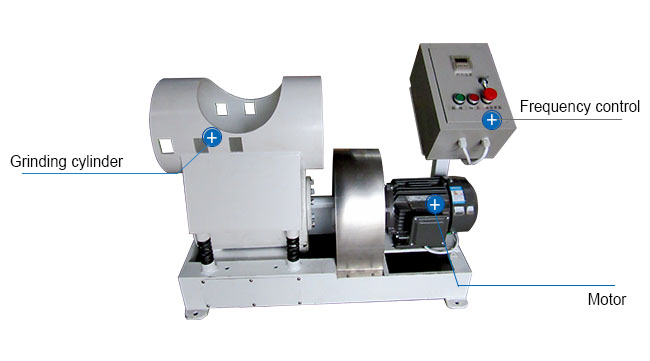

Vibration ball mill is mainly composed of machine frame, chassis, vibration exciter, grinding cylinder, spring, and motor. When the machine starts up, the motor drives the vibration exciter to generate an exciting force to make the grinding cylinder continuous vibrating with high frequency and small amplitude. As rotation and relative movement of the grinding medias produce frequent impacts and grinding & stripping effects on the materials, purpose of crushing materials in uniform will be achieved.

1. As the loading amount of vibration ball mill grinding medias inside the cylinder is higher than that of the other ball mill in same size, it reaches 80% of the cylinder volume, so vibration ball mill often has much larger processing capacity.

2. It has simple structure, and it produces different particle sizes of output powder by adjusting the amplitude, frequency, medium, and ratio.

3. vibrating ball mill with a jacketed mill barrel can adjust grinding temperature

4. The vibration ball mill with sieve and collection device can be used for continuous production

5. Simple and convenient operation, reliable work, easy to clean, and strong adaptability under working conditions.

6. It can be used for dry and wet ball milling.

7. Light weight, small volume and high efficiency.

8. It can be customized according to customer’s requirements.

Details of Structure Of Vibration Ball Mill