How to select a agitator bead mill, KEY points?

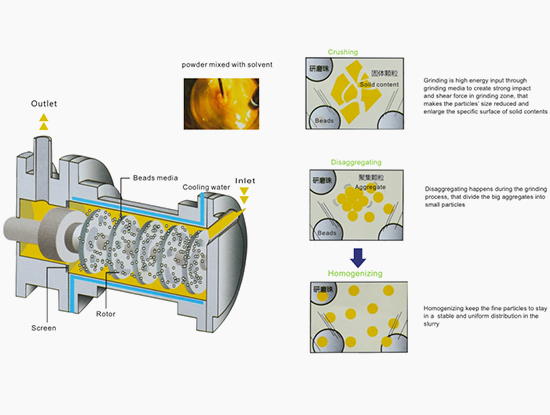

A. Flow rate of bead mill determines how long time the particles stay in the grinding zone,which affects the fineness of particles, output and particle size distribution.

B. Linear velocity of rotor determines the intensity of kinetic energy that transffered to the grinding media which affects the grinding efficiency, fineness of particles and wear loss of grinding media. 12-16 m/s is the generally operation speed.

C. Grinding media size selection is a key point, usually it is 1000 times of the target particle size. In theory, smaller the diameter of the beads is, more the contact point exists with smaller particle size achievements. However, It still depends on many factors like initial particle size. We need to choose the correct beads to fit different grinding requirements.

D. Generally, the grinding media filling rate is higher, the grinding efficient is higher. And the range of filling rate is around 75%-90% according to the viscosity of products. If too much higher will cause sieve blocking and high temperature problem.

E. Bulk density of grinding media-higher the bulk density will create stronger shear and impact force in the movement , better grinding efficiency it is.

F. Gap of separation screen is usually 1/2-1/4 times of the grinding media diameter. If the particle initial size is much bigger, it may block the sieve, hence, we need to consider two stage grinding process

| Model | Active Volume | Power

(KW) |

Batch Size

(L) |

Media size

(mm) |

Weight

(kgs) |

Dimensions

(mm) |

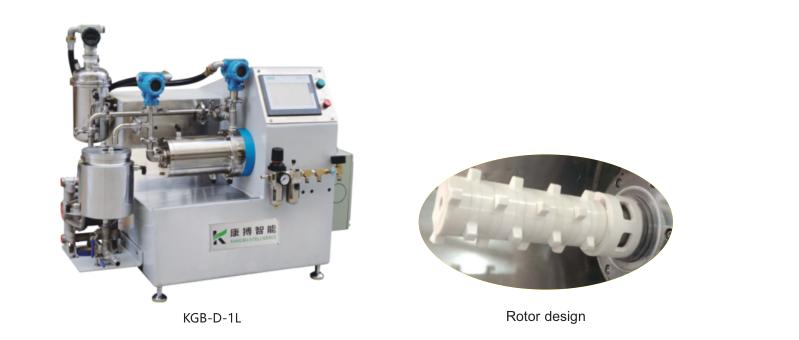

| KGB-D-1L | 1L | 5.5 | 3-20 | 0.6-2.0 | 190 | 480*400*550 |

| KGB-D-5L | 5L | 11 | 30-200 | 0.6-2.0 | 450 | 900*700*1500 |

| KGB-D-25L | 25L | 30 | 80-800 | 0.6-2.0 | 1100 | 1700*1100*1900 |

| KGB-D-30L | 30L | 30/37 | 80-1000 | 0.6-2.0 | 1300 | 1750*1100*1900 |

| KGB-D-50L | 50L | 45 | 200-2000 | 0.6-2.0 | 1700 | 2100*1500*1750 |

| KGB-D-60L | 60L | 55 | 250-2500 | 0.6-2.0 | 1850 | 2150*1500*1750 |

| KGB-D-100L | 100L | 90 | 300-4000 | 0.6-2.0 | 2600 | 2600*1650*1900 |

| KGB-D-150L | 150L | 130 | 500-4000 | 0.6-2.0 | 3500 | 2900*1650*2100 |

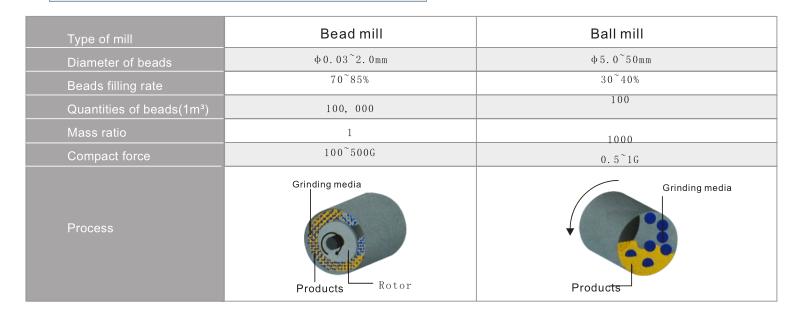

Comparison between bead mill and ball mill

General Applications of Bead Mill

New energy_Lithium-ion battery, lsilicon carbon, graphene, carbon nanotubes, alumina membrane slurry, PVDF membrane slurry, etc.

Powder_Alumina, Zirconia, Silicon Carbide, Titanium Dioxide, Calcium Carbonate, Silicon Materials, Cerium oxide, Zinc oxide, Barium Titanate, MLCC, Boron Nitride, Boron carbide, magnetic materials, etc.

Chemical_Automotive coating, furniture paint, anticorrosive paint, special paint, color paste, ceramic ink, UV ink, glass ink,offset ink, cosmetics, pharma , food, agriculture and others to provide a complete set of solutions.

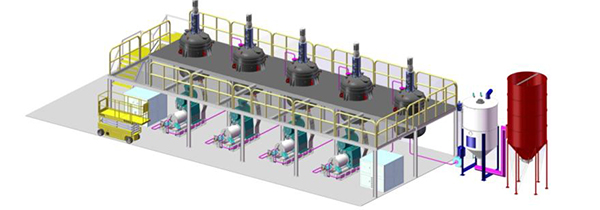

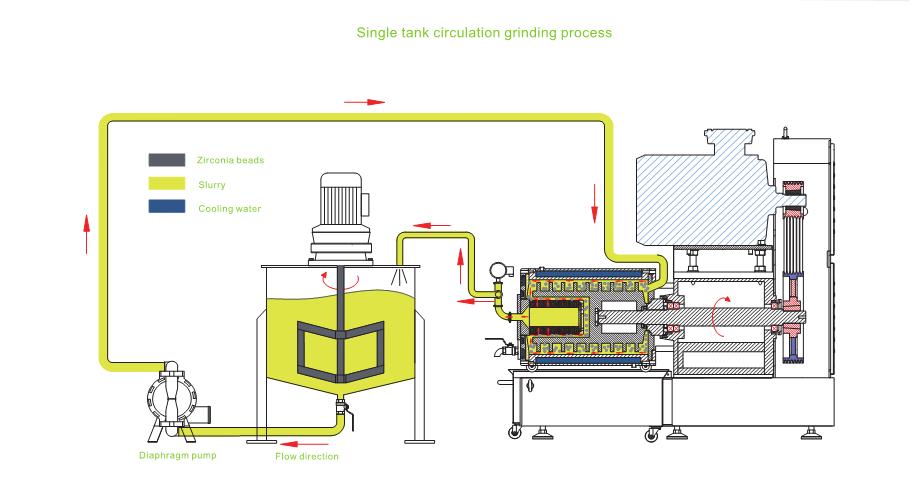

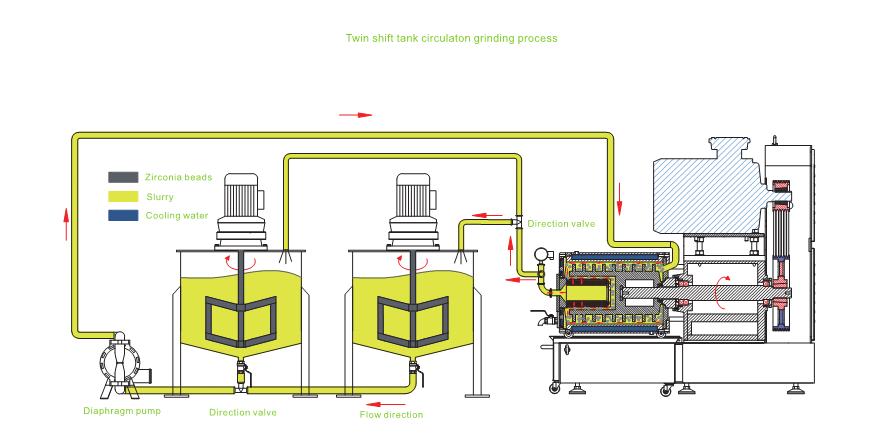

Automatic production line platform

KGB-D Series Of Rod Pin Bead Mill

Applications Of Rod Pin Bead Mill

Lithium cathode and anode materials, industrial ceramics (alumina, zirconia and other oxides, silicon carbide, boron carbide, zirconium silicate, silicon nitride, nitrogen compounds, nano polishing fluid (alumina, zirconia, cerium oxide, etc.),

graphite, graphene, advanced materials, electronic ceramics, nano paste, Inkjet ink, Ink (Ceramics, UV, Glass, etc.), pharmaceutical, pesticide, magnetic materials.