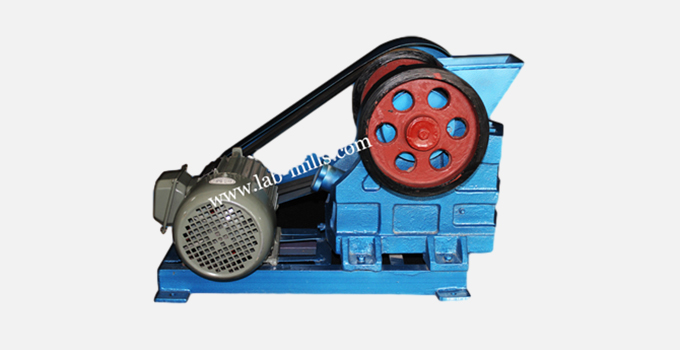

Is mainly used to crush a variety of ores and bulk materials with comprehensive strength of less than 320Mpa in middle granularity. PE series of lab jaw crusher has full specification, its feed size of materials ranges 125mm~1200mm, and it is the preferred primary crushing equipment. The equipment is mainly applied to crush materials in rough, medium and fine scale such as ore limestone, calcium carbide, carbide slag, shale, basalt , river gravel, blue stone, etc. The machine has a significant performance in cement plants, gravel plants, stones factory, thermal power plants desulfurization, calcium carbide plant, and it is widely used in mining metallurgy, chemical industry, building materials, water conservancy, transportation and other industries.

|

Technical Parameters of Lab Jaw Crusher |

||||||||

| Model No. | Capacity (kg/h) | Material Inlet Size(mm) | Feeding Size(mm) | Out-put Particle Size (mm) | Spindle Speed (rpm) | Power

(KW) |

Power Supply

(V) |

Net Weight

(KGS) |

| XPC100*60 | 230-400 | 100×60 | 50 | 6-10 | 650 | 1.5 | 380V/50Hz | 350 |

| XPC100*100 | 200-1800 | 100×100 | 80 | 3-25 | 600 | 2.2 | 380V/50Hz | 300 |

| XPC125*100 | 200-1800 | 125×100 | 80 | 5-25 | 500 | 3 | 380V/50Hz | 300 |

| XPC100*150 | 200-1800 | 100×150 | 90 | 6-38 | 500 | 2.2 | 380V/50Hz | 360 |

| XPC150*125 | 400-3000 | 150×125 | 100 | 6-38 | 500 | 3 | 380V/50Hz | 417 |

| PE150*250 | 700-5000 | 150×250 | 120 | 10-40 | 350 | 5.5 | 380V/50Hz | 500 |

| PE60*100 | 45-550 | 60×100 | 50 | 1-10 | 290 | 1.5 | 380V/50Hz | 80 |

| PE100*100 | 65-850 | 100×100 | 80 | 1-25 | 600 | 2.2 | 380V/50Hz | 320 |

| PE100*125 | 300-2000 | 100×125 | 100 | 2-35 | 375 | 3.0 | 380V/50Hz | 360 |

| PE 150*125 | 500-3000 | 150*125 | 125 | 4-45 | 375 | 3.0 | 380V/50Hz | 380 |

The main structure of lab jaw crusher: frame, eccentric shaft, big pulley, flywheel, side guard ,elbow board, elbow board seat, adjusting screw rod, the return spring, fixed board and adjusted jaw board, and the elbow board can play a role as Protector. The broke drive model of this series jaw crusher is curved extrusion. Motor-driven belt and pulley, through the eccentric shaft to let the jaw up and down, when the movable jaw rises bracket, and the angle Motor-driven belt and pulley, through the eccentric shaft to move jaw up and down movement, when the movable jaw rises, the angle between elbow board and movable jaw plate becomes larger, thus promoting the movable jaw plate close to the fixed jaw plate, while the material can be crushed by squeezed, rubbing, grinding. When the movable jaw fall down, the angle between elbow board and movable jaw becomes smaller, the movable board will leave the fixed jaw board by the action of rod and spring, at the same time crushed material is discharged through crushing chamber.

1.The crusher ratio can reach to about 13 in uniform size;

2.Adopt gasketed nesting population adjustment device,the adjusting range is big and reliable operation;

3.High efficiency,low energy consumption,compared with common small jaw crusher,it’s processing capacity 20%-35% higher than that of the same specification,and can reduce the energy consumption of 15%-20%;

4.Deep crushing chamber has no dead zone and can increase the feed ability and production capacity;

5.The use of small wear hyperboloid jaw plate service life can be prolonged by more than 3-4 times in the same process conditions,especially to the high abrasive material is more obvious;

6.The lubrication system is safe and reliable, convenient replacement parts, maintenance workload is small.