Has four ball grinding tanks installed on one turntable. When the turntable rotates, the tank axis makes planetary movement and the balls inside the jars grind and mix materials in high speed movement. The product can smash and blend various products of different materials by dry or wet grinding methods. Smallest particle size of ground powder can be reached to 0.1 micron. As the mill jars are loaded into the jar holders horizontally with only one bottom end fixed on the planetary disc, we often call it as light type or laboratory model.

|

Technical Features of Horizontal Planetary Ball Mill Light Type |

|

| Drive Mode | Gear drive and belt drive |

| Operation Mode | Two or four mill jars can be used for each grinding |

| Maximum Loading Capacity | Less than 1/3 of each jar volume Total max capacity: less than 1/3 of total jars volume |

| Feeding Size | Soil material≤10mm, other materials≤3mm |

| Output Granularity | Smallest granule reaches to 0.1 μm |

| Rotational Speed Ratio | 1/2 |

| Max. Continuous Operating Time | 72hours |

| Optional Modes of Speed Control | Frequency conveter and automatic timing control |

| Materials of Jar | 304 Stainless steel, 316l stainless steel, Zirconia, Nylon, PU, Alumina ceramic (corundum), PTFE, Agate, Tungsten carbide |

Table 1 Technical Parameters For Horizontal Planetary Ball Mill Light Type

| Model No. | Specifications | Matchable Sizes

of Mill Jars |

Matched Quantity | Matchable Sizes

of Vacuum Mill Jars |

| WXQM-0.4 | 0.4L | 50ml, 100ml | 4 pcs | 50ml |

| WXQM-1 | 1.0L | 50ml, 100ml, 250ml | 4 pcs | 50ml. 100ml |

| WXQM-2 | 2.0L | 50ml-500ml | 4 pcs | 50ml, 100ml, 250ml |

| WXQM-4 | 4.0L | 250ml-1000ml | 4 pcs | 50ml-500ml |

| WXQM-6 | 6.0L | 1L-1.5L | 4 pcs | 50ml-750ml |

Table 2 Technical Parameters For Horizontal Planetary Ball Mill Light Type

| Model No. | Voltage | Power | Rotation Speed | Noise |

| WXQM-0.4 | 220V-50Hz | 0.75KW | 70-670 rpm | Less than 58db |

| WXQM-1 | 220V-50Hz | 0.75KW | 70-670 rpm | Less than 60db |

| WXQM-2 | 220V-50Hz | 0.75KW | 70-670 rpm | Less than 60db |

| WXQM-4 | 220V-50Hz | 0.75KW | 70-670 rpm | Less than 60db |

| WXQM-6 | 220V-50Hz | 0.75KW | 70-670 rpm | Less than 60db |

Table 3 Technical Parameters For Horizontal Planetary Ball Mill Light Type

| Model No. | Speed Control | Net Weight | Net Dimensions |

| WXQM-0.4 | Frequency Control | 86kgs | 700*510*570mm |

| WXQM-1 | Frequency Control | 86kgs | 700*510*570mm |

| WXQM-2 | Frequency Control | 86kgs | 700*510*570mm |

| WXQM-4 | Frequency Control | 86kgs | 700*510*570mm |

| WXQM-6 | Frequency Control | 86kgs | 700*510*570mm |

Horizontal Planetary Ball Mill has four ball grinding jars installed on one turntable. When the turntable rotates, the tank axis makes planetary movements, the balls and samples inside the tanks are impacted strongly in high speed movement, and samples are eventually ground into powder. A variety of different materials can be ground by dry or wet method. Minimum granularity of ground powder can be as small as 0.1μm.

1. Easy operation.

2. Unique gear with low noise.

3. Horizontal structure of the mill pots prevents materials from sinking to the bottom of jars.

1. Stable revolving speed of the gear transmission ensures the consistency and repeatability of the experiment.

2. Planetary movement principle is adopted in the machine, which has high speed, large energy, high efficiency, small Granularity.

3. Four powder samples from different sizes and different materials can be produced at one time.

4. The machine is controlled by frequency converter; you may choose ideal rotating speed according to expected experimental result. The converter is equipped with device of under voltage and over-current to protect the motor.

5. The planetary ball mill has functions of timing power off, self-timing forward and reversal rotating. You may choose freely any operation modes of one-way direction, alternation, succession, and timing according to experimental needs so as to improve efficiency of grinding.

6. Technical features of Tencan Ball Mill: Low center of gravity, stable performance, compact structure, easy operation, reliable safety, lower noise, small loss.

7. Safety switch is installed on the machine to prevent safety accident if the safety cover is opened while machine is running.

Accessories

We provide all kinds of mill pots in any matched size, which are made from following materials of agate, Alumina corundum ceramics, zirconia ceramics, silicon nitride ceramics, carborundum ceramics, stainless steel, high wear resistant steel, manganese steel, nylon, PU, cemented carbide, crystal glass, and etc.

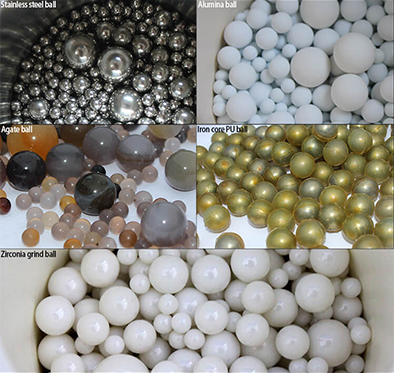

We can also provide all kinds of mill balls like stainless steel balls, zirconia balls, alumina balls, PU balls, steel carbon balls, tungsten balls, agate balls, hard metal balls, silicon nitride balls, high wear resistant steel ball, manganese steel balls, nylon balls, cemented carbide, crystal glass and other special metal materials.

|

Recommendation For Matching Solutions About Mill Jars & Materials |

|

| Categories of Materials | Recommended Mill Jars |

| Soil and other Materials which are not allowed with any impurity | Agate mill jar |

| Metal & nonmetal materials which are not allowed with any impurity | Zirconia mill jar |

| High hardness materials like diamond, tungsten carbide | Tungsten carbide mill jar |

| Strong add & alkali materials or other materials at high temperature | PTFE mill jar |

| Iron ore materials with lower impurity sensitivity | 304 Stainless steel mill jar |

| Pigment or other materials with later process under high temperature | Nylon mill jar |

| Aluminum materials like ceramic glaze | Corundum mill jar |

| Electronic materials like lithium battery | Polyurethane mill jar |

| Easily oxidized materials or some special materials which need to be protected under special atmosphere. |

Vacuum mill jar |

|

References About Grinding Medias & Materials |

||

| Materials of Grinding Media |

Hardness (Mohs) |

Features |

| Zirconia Balls | ≥9.0 | Super wear-resistance, without any impurity, corrosion & high temperature resistance. |

| Stainless Steel Balls | ≥6.0 | Wear-resistant, general corrsion resistance, high temperature resistance. |

| Agate Balls | ≥7.0 | Super wear-resistance, used for medicine,food and other materials which can not be contaminated with metal, corrosion, and high temperature resistance. |

| Alumina Balls | ≥8.5 | Wear-resistant, corrsion resistance and high temperature resistance. |

| Tungsten Carbide Balls | ≥9.0 | Super wear-resistance, without any impurity, corrosion & high temperature resistance. |

|

Matching Solutions for Mill Jars & Balls |

|||||

| Items | Agate Balls | Alumina Balls | Stainless Steel Balls | Zirconia Balls | Tungsten Carbide

Balls |

| Agate Mill jar | √ | ||||

| Corundum Mill Jar | ▲ | √ | ▲ | ||

| Stainless Steel Mill Jar | √ | ||||

| Zirconia Mill Jar | ▲ | √ | |||

| Nylon Mill Jar | ▲ | √ | |||

| PTFE Mill Jar | √ | ▲ | |||

| Polyurethane Mill Jar | √ | ▲ | |||

| Tungsten Carbide Mill Jar | ▲ | √ | |||

| √ means: most suitable ▲ means: suitable | |||||