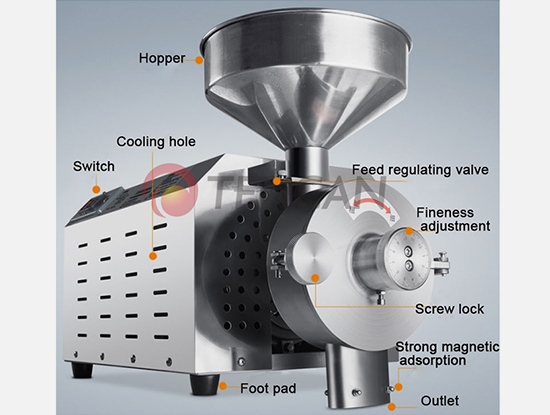

Grain mill is also named as small mill, which grinds all kinds of grain, Chinese herbal medicine and other foods into 50-200 mesh uniform powder. The machine is made of high quality stainless steel and is made with fine machining technology. The small mill is operated by two grinding plates full of teeth to grind the materials into powder. It can grind various grains, Chinese medicinal materials, condiment raw materials and other materials into 50-200 mesh uniform powder.

| Item No. | Model No. | Voltage (V) | Power (KW) | Rotation Speed

(rpm) |

Capacity

(Kgs/h) |

Feed size

(mm) |

Fineness

(mesh) |

Net Weight

(kgs) |

Dimensions

(mm) |

| 1 | MF2200 | 220/380 | 2200 | 1540 | 30-50 | ≤10 | 50-200 | 50 | 690*380*400 |

| 2 | MF3000 | 220/380 | 3000 | 1450 | 30-50 | ≤10 | 50-200 | 55 | 690*380*400 |

| 3 | MF3500 | 220 | 3500 | 1450 | 30-50 | ≤10 | 50-200 | 70 | 750*380*400 |

| 4 | MF4000 | 380 | 4000 | 1450 | 30-50 | ≤10 | 50-200 | 70 | 750*380*400 |

The grain mill is mainly composed of a feed hopper, a rotor, a toothed disc, a screen, a casing, a frame, and a motor. When material enters the crushing chamber, it will be rapidly crushed into fine powder or slurry under continuous impact of round teeth and flat teeth and impact of the toothed plate. Under actions of centrifugal force and air flow, the crushed fine powder will be discharged through the screen hole of the outlet.

1.Convenient operation

2.The parts in contact with the materials inside the machine cavity are free of grease, which keeps the hygiene and cleanness of the materials, and does not need any lubricant, thus ensuring cleanness and no pollution.

3.The grain mill has quite small noise. The parts are processed by precision machining and are strictly inspected based on inspection procedures. After assembly, the machine is tested by the engineering personnel and strictly checked at all levels, which ensures that the grain flour mill strictly meets requirements of design. working noise of the machine is small and will not affect the surrounding environment, so that every customer feels at ease, moreover, the processed and finished products meet the basic requirements of delicacy and hygiene.

4.With repeated efforts of the R & D personnel, the grain mill has good performance of fine grind and lower noise, the grain mill can grind materials with high oil content or high sugar content into very fine powder such as sesame, walnut, almonds, cucumber seeds, winter melon seeds, wolf berry and Codonopsis pilosula, which solves the problem that ordinary mills cannot grind the above materials.