Agate mortar grinder is also called agate bowl grinder or agate grinder, which is mainly composed of grinding rod, agate mortar and scraper. During the clockwise rotation of agate mortar, the grinding rod will roll the solid particles of material in the mortar to make the solid particles smaller and thinner. At the same time, the stationary scraper will scrape the particles off the edge of the mortar, so that the solid particles return to the mortar and continue to be milled. During the rotation of agate mortar and the movement of grinding rod, the grinding opportunities for each solid particle are equal, so the particle size of the ground micro powder is uniform. Set a reasonable milling time for different solid particles (generally, the longer the milling time, the finer the particles are milled), so that the coarse particles and fine particles can be both milled into very fine powder particles. some particle size can reach the micron scale, and some even reach the nano powder scale. The whole milling process can be automatically controlled. Agate bowl mill is an ideal grinding equipment for grinding a small amount of micro-powder in the laboratory.

| Description of Items | Technical Parameters |

| Product Name | Agate Mortar Grinder |

| Model No. | MNY-Φ120 |

| Max Capacity | 30g |

| Power Supply | 220V-50Hz 1 Phase or 110V-60Hz 1 Phase |

| Power of Agate Bowl | 0.1KW |

| Power of Grinding Rod | 0.25KW |

| Material of Bowl & Rod | Agate |

| Mortar Diameter | Ø120mm |

| Depth of Grinding Bowl | 34mm |

| Rotation Speed of Grinding Bowl | 10 rpm |

| Rotation Speed of Grinding Rod | 20-90 rpm |

| Feed Size of Material | ≤1.5mm |

| Output Size | 0.074mm |

| Grinding Time | 1-900 min |

1) The final particle size of grinding materials can reaches micron level.

2) Rotation speed and grinding time can be controlled precisely.

3) It is used for grinding super hard materials into micro powder, electronic micro powder, resin micro powder, food micro powder, pharmaceutical micro powder and chemical micro powder.

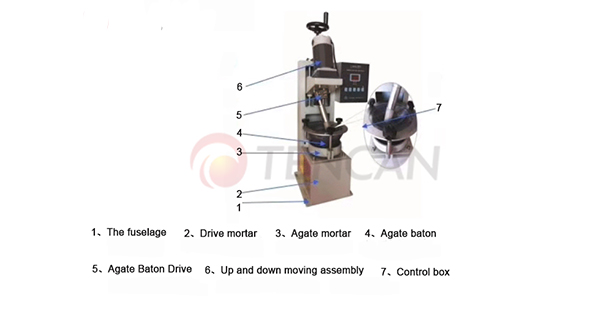

4) Simple structure and easy operation.