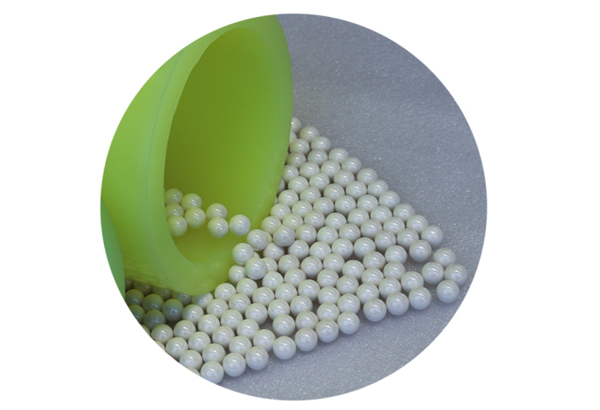

Grinding ball is a kind of grinding medium for ball mill machines. China Tencan has a wide variety of grinding balls in full sizes like 304 or 316L stainless steel balls, tungsten carbide balls, agate balls, alumina balls, zirconia balls, silicon nitride balls, and etc. Grinding balls are commonly used for grinding and dispersing ultra-fine powder and they can be matched with all kinds of planetary ball mill, roll ball mill, stirred ball mill, vibrating ball mill and so on.

Grinding balls are commonly used for grinding and dispersing ultra-fine powder and they can be matched with all kinds of planetary ball mill, roll ball mill, stirred ball mill, vibrating ball mill and so on.