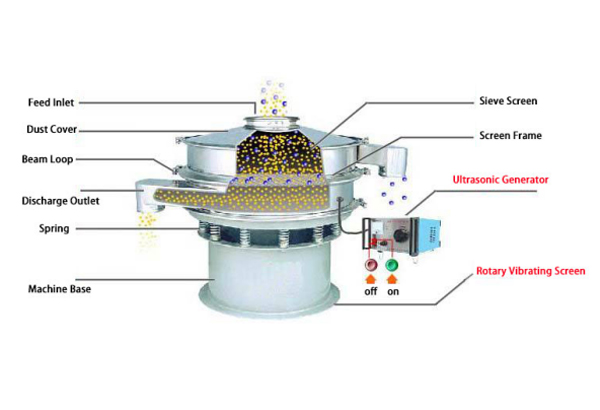

The ultrasonic vibrating screen is to transform the electric energy of 220V/50Hz or 110V/60Hz into high-frequency electric energy of 18khz, input the ultrasonic transducer, and turn it into the mechanical vibration of 18khz, so as to achieve purpose of high-efficiency screening and mesh cleaning. Based on the traditional vibrating screen, the system introduces a low amplitude and high frequency ultrasonic vibration wave (mechanical wave) on the screen and superimposes a high frequency and low amplitude ultrasonic vibration wave on the screen, where the ultra-fine powder receives a huge ultrasonic acceleration, so that materials on the screen surface remain to be kept in suspended state all the time, so as to suppress blocking factors such as adhesion, friction, level drop, wedging, etc. Ultrasonic vibrating screen solves normal screening issues such as strong adsorption, easy agglomeration, high static electricity, high precision, high density and light specific gravity, it becomes much easier to sieve ultra-fine powder (above 200 meshes) with this model.

|

Ultrasonic Vibrating Screen Technical Parameters |

|||

| Frequency | 34KHz | Overall Dimension | 345mm*320mm*145mm |

| Power | 220V~240V50/60HZ | IP Code | IP55 |

| Working Mode | Continuous | Adjustment Range | 50~100% |

| Temperature | 45°C | Transducer | Offset |

1. Ultrasonic adopts integrated circuit board, fully sealed, digital CPU control. it works continuously for 12-24 hours without cooling treatment.

2.The mesh is not easy to be blocked and it can be self-cleaned by ultrasonic.

3. It is suitable for screening 40-635 mesh size, especially for above 300 mesh fine powder.

4. Easy to be operated and maintained.

5. High efficiency for screening super-fine powder. It solves screening problems effectively

such as strong adsorption, easy agglomeration, high static electricity, high precision, high density, light specific gravity, and etc.

Ultrasonic Vibrating Screen is widely used in metallurgy powder, electromagnetic materials, metal powder, iron powder, zinc oxide, alumina powder, alloy powder, molybdenum powder, cobalt powder, carborundum, copper, nickel powder, silica powder, titanium oxide, tungsten carbide, tungsten powder, titanium powder , stainless steel powder etc.