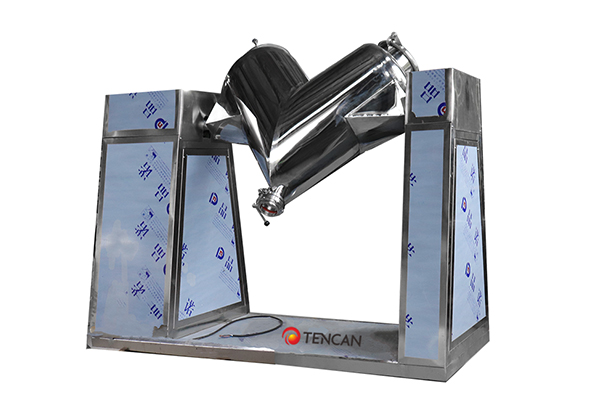

V-type mixer machine is suitable for pharmacy,food,chemical, metallurgy,electronics and other industries, used for mixing the dry granule materials. The machine adopts manual feed and closed disc valve discharge, which can avoid dust spilling; with unique mixing barrel structure, high efficiency blending, and no dead angle. Using stainless steel material, prevent the mixing materials from being polluted.The inside and outside of machine are polished. Mixing the materials evenly and apply to a wide range of fields. It also can be equipped with the compulsory mixer, which is according to the users’ demand. It is suitable for smaller powder, blocks and the material that contain a certain mixture of water.

V-type mixer is applied to industries of pharmacy, food, chemical engineering, metallurgy, electron, which need to mix two or more kinds of dry powder and particles. With such a special structure of V-type mixing tank, materials inside are turning around repeatedly to achieve uniform mixing. The machine has many features such as no dead angle, high speed, short mixing time, uniform mixing.

| Model | Speed

(r/min)±2 |

Fix Speed (r/min)±2 | Motor (KW) | Motor

Grade |

Power

Supply |

Capacity (L) | Dimensions

(mm) |

Weight

(KGS) |

| V-5 | 10-50 | 50 | 0.37-B5 | 4 | 220V/1ph | 2.5 | 1060*410*890 | 78 |

| V-10 | 10-50 | 50 | 0.37-B5 | 4 | 220V/1ph | 5 | 1060*410*890 | 82 |

| V-20 | 8-34 | 34 | 0.75-B5 | 4 | 220V/1ph | 10 | 1360*480*980 | 139 |

| V-50 | 8-34 | 34 | 1.5-B5 | 4 | 220V/1ph | 25 | 1680*510*1270 | 200 |

| V-100 | 8-34 | 34 | 2.2-B5 | 4 | 380V/3ph | 50 | 1570*475*1500 | 280 |

| V-200 | 5-24 | 24 | 3-B5 | 4 | 380V/3ph | 100 | 1980*770*1680 | 379 |

| V-300 | 5-20 | 20 | 4-B5 | 4 | 380V/3ph | 150 | 2000*800*1800 | 698 |

| V-400 | 4-12 | 12 | 5.5-B5 | 4 | 380V/3ph | 200 | 2300*1000*2000 | 820 |

| V-500 | 4-12 | 12 | 7.5-B5 | 4 | 380V/3ph | 250 | 3120*1850*2100 | 1150 |

V-type mixer machine is composed of container welded with two cylinders. Shape of cylinder is asymmetric. Because of rotary motion, granule powder is segmented and merged continuously and repeatedly, feed material is delivered from one to another, and powder particle is stacked multiplexer with slip of powder and is constantly distributed on surface of powder.

1. High efficiency for mixing materials at close or same granularity and density

2. It is not easy to crush granule when mixing materials.

3. The machine keeps material particle integrity without extrusion and strong wear.

4. Internal and external of the mixing vat are polished without dead angle, to avoid cross contamination of materials.

5. Available materials of mixing vat: carbon steel, stainless steel, nylon, and etc.

6. The machine is equipped with a timing device, it can set mixing time to realize automatic stop.